Introduction |

||||

New products for superyachtsIn response to a customer's request for a SiedarcTM electrode in a stainless thruhull, we have developed a new top-end product featuring a nickel-plated electrode in a stainless 316 thruhull that will look good in the hull of any superyacht.For the same type of vessel, we can also fabricate low-profile air terminals for flush installation in fiberglass handrails and hard tops to maintain clean lines: from outside the yacht, no rods are visible. Mechanism for SiedarcTM electrodesCharge on water surfaceA recent report from one of our customers has shed some light on how our electrodes function - by forming sparks just above the water surface that neutralize the ground charge residing on the surface. See the discussion and animation on our Science page, or click here for a preview.Latest statisticsBad News for CatamaransBoat US has released their latest statistics for lightning claims. These show that not only are there twice the frequency of multihull claims, compared with monohulls, but also the average claim is 67% higher. See all the statistics here. Also, we explain the higher strike frequency for catamarans in terms of their larger footprint. This leads us to conclude that you can increase your risk by 5-10 times when you anchor out, even if you are in a monohull!New standard - NFPA 780-2008Protect a boat Like a buildingThe October 2007 edition of Boat US's Exchange explains this novel concept. See the article here. This concept has been incorporated into the new National Fire Protection Association Lightning Protection Standard NFPA780-2008, which is now available. The watercraft section is Chapter 8.Latest projectSeadoo GTX155 jet skiThis interesting challenge arose from a planned ride from London to Sydney by jetski. Since the route includes the tropical Pacific, team leader Jeremy Burfoot wisely decided to add lightning protection to the two jetskis involved. See here for system details.Other projectsSee our Systems Gallery for pictures and descriptions of systems on all types of power and sail boats. |

||||

PrinciplesPeer-reviewed science forms the basisOur approach to lightning protection is based solidly on observation and scientific theory. The foundation was established in a paper published in 1991 in the prestigious IEEE Transactions of Electromagnetic Compatibility. As a result of this paper, subsequent renditions of standards published by ABYC and NFPA upgraded their recommended sizes for down conductors from #8AWG to #4AWG and noted that a ground strip is a more effective grounding conductor than a square plate of the same area.Another fundamental problem revealed in this scientific work was that a one square foot ground plate is "hopelessly inadequate" to prevent sideflashes in fresh water.This was not addressed in these earlier standard rewrites since, at the time, there was no obvious solution. We can now solve this problem with our patented SiedarcTM electrodes that, when distributed around the hull, provide the multiple exit points needed for effective grounding. More recently, we have worked with the NFPA 780 technical committee to establish a new standard based on these new ideas, that is now published as Chapter 8 in the 2008 version of NFPA 780 This standard is based on the simple concept that a boat should be protected the same as a building, with the lightning conductors on the outside rather than through the middle of the boat. As the ground attachment path for a 5-mile long spark carrying tens of kiloamperes, the protection system has the task of safely diverting this current around crew, sensitive electronics, and hull components. However, even when the current is flowing in the water, voltage differences can cause sideflashes, both inside the boat and between the boat and the water. These present a shock hazard to the crew, produce overvoltage in electronics systems, and can blast holes through the hull. Management of the sideflash problem is the fundamental issue in the design of an effective marine lightning protection system. Grounding Concepts page for a technical explanation of the underlying concepts and suggestions as to how these can be applied to a protection system. Sideflash management is the objectiveAn interesting feature of hull damage is the tendency for sideflashes to form around about the waterline. Apparently either the water surface or the waterline itself causes charges to accumulate, usually on internal conducting fittings, and initiate sparks through the hull. The effect is more pronounced in fresh water than salt. In

lightning protection circles, the conventional solution to a problem such

as this is to add conductors where the damage is observed.In the above case this means placing

lightning conductors through the hull at the waterline.Since it is impractical to install

multiple ground plates in a hull, we developed the SiedarcTM electrode to provide the necessary exit terminals. This is effectively an air terminal near

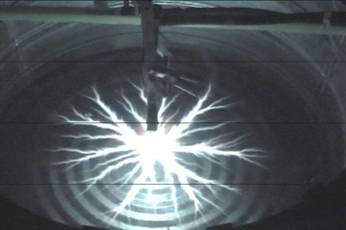

the water.In fact, each In order to investigate the effectiveness of this concept, we tested an electrode with a 10kV generator for both salt and fresh water at Kennick Inc. in St. Petersburg. Even though 10kV is much lower than what would be expected during a lightning strike, we obtained results that clearly indicated the promising potential for the method and further elucidated the best mode of operation. Specifically, in the photo below, with the electrode about 1/4 "above the surface of salt water, a spark of about 15" in diameter was produced. Clearly the sparking is contained very close to the water surface, perhaps even above it, showing the importance of the surface for current dissipation. In fresh water, the spark connected all the way to the sides of the container, about 12" away. In contrast, when the electrode tip was immersed just below the water surface, a small (~1/2") glow was observed but no sparks. The conclusion is that an electrode can generate a spark that is orders of magnitude longer than the spark gap in air when placed above the water surface. Hence the optimum placement is just above the water surface. The animation below illustrates how we expect the SiedarcTM electrodes to function. See our Science page for more details

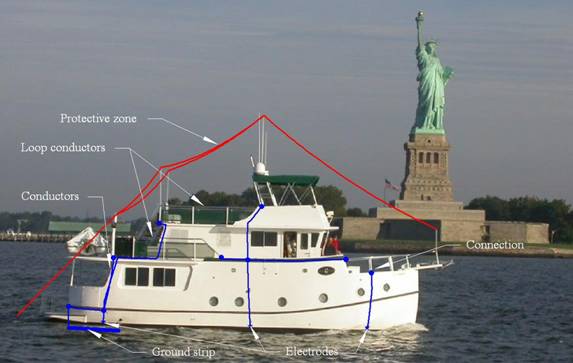

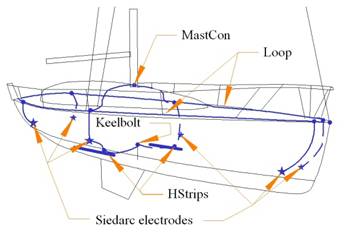

Providing exit terminals around the perimeter of the hull is the key to an effective system design since, in addition to dispersing the current more uniformly around the boat, it also enables the lightning down conductors to be routed externally to all wiring and conducting fittings. This is illustrated for a sailboat on the right. The lightning conductor from mast base connects to both the chainplate and the loop before passing down to a daisy-chain SiedarcTM electrode just above the waterline, and from there via an immersed HStripTM to a keelbolt (and base of a keel-stepped mast). SiedarcTM electrodes at bow and stern provide more exit terminals from the loop to the water. This geometry is mirrored on the port side, as indicated by the dashed lines. That is, there is a total of two HStrips and six SiedarcTM electrodes. Thus a conducting grid covers the interior of the boat and a total of eight exit terminals are distributed over the hull near the waterline. For a keel-stepped mast, make another connection from the mast base to the keelbolt of HStrips. Guiding the current on the outside rather than through the middle of the boat minimizes shock risk and emi. In addition, a bonding loop around the boat at about deck level equalizes potentials, provides additional paths for current flow, and can be used for bonding conducting fittings. In a major departure from the status quo, NFPA (the National Fire Protection Association) has recently revised their watercraft standard (NFPA 780 Ch.8) to include the concepts of a loop conductor, external down conductors, and perimeter grounding electrodes. See our Standards page for details. With this new system the conductor layout more closely mirrors that found on the typical lightning protection system on a building. We call this system of external lightning conductors and peripheral exit terminals the ExoTerminalTM protection system. In the photo below, we have shown where additional (internal) lightning conductors, grounding terminals, and air terminals were installed to fabricate this type of system. Products & servicesWe can provide all of the components needed in a marine lightning protection system - air terminals, connections, grounding strips and SiedarcTM elecrodes. See our Products page for details.We also offer consulting services for:

Contact

Please call or email if you have any questions.

| ||||

one is designed to the same specification

as a lightning air terminal.

one is designed to the same specification

as a lightning air terminal.