Patrol boatOverview

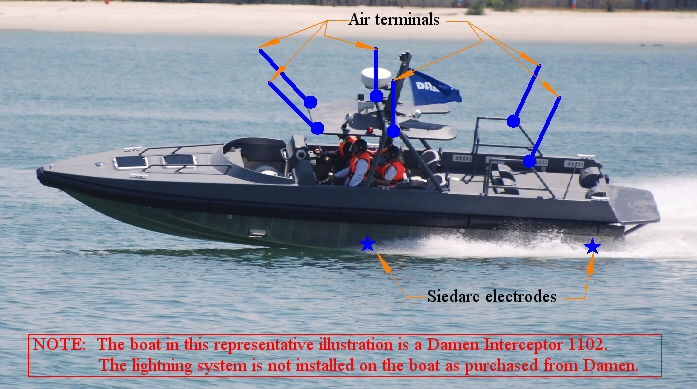

Special hazardsWhether the patrol involves interception or rescue, being able to operate in all types of weather is a prerequisite for this type of craft. Since operations are possible in the middle of severe storms, safety for the crew is paramount, and survivability of engine electrical systems and communication electronics is highly desirable.LayoutA generic system for an aluminum hulled boat is shown below. Additional lightning conductors and grounding electrodes would be required for an fiberglass hull.

Surge suppressors on communication antennas improve the survivability of these key systems. In order to place all crew members in a zone of protection, the tips of the external air terminals are higher than the head of a crew member. This provides far superior protection to a single rod, and the air terminals can be much lower. provide external paths for the lightning current. The aluminum hull provides the necessary electrical connections between the air terminals and the grounding electrodes. The two electrodes at the stern of an aluminum vessel provides alternative discharge paths to the engine outdrives to lower the risk of engine damage while the two electrodes amidships offer a direct path to the water surface whether the craft is sationary or moving at top speed. System featuresOur recommended lightning system is shown in the above figure with the features discussed below. Whole boat coverageBy placing air terminals externally and at several points on the hardtop and rails, we develop a protective zone that, according to the rolling ball model, covers all members of the crew. See our Air terminals page for more details on protective zones.Energy from a lightning strike diverted efficiently to the waterObservations of surface discharges from lighting strikes and high voltage discharges indicate that the most efficient way to divert the lightning electrical energy from the boat is towards the surface of the water where the charge to be neutralized resides. See our discussion of the discharge mechanism for this process. Our approach to the grounding issue is to add electrodes to the hull just above the waterline to intiate these surface discharges. For this application we recommend our nickel-plated copper electrodes in a stainless through hull, with two aft for enhanced protection of the engines, and two amidships directly below the hard top and air terminals.Surge protectors for all antennasEven when the lightning attaches to an air terminal, upward discharges can be expected off any exposed antennas, even those that are inside the theoretical protective zone. As indicated in this specification, surge suppressors are needed. The"grounding" connection from these is connected to the lightning protection system or anywhere on the hull. The geometry for this connection is important to minimize inductive voltages.Grounding both at rest and while movingThe advantage of Siedarc TM electrodes in this application is that they are designed to form a grounding discharge in the air above the water surface. Hence it makes little difference if the interceptor is stationary or at a full plane.Bonding to electrical system groundTheoretically (section 4.3.2 in our Grounding Concepts page), any internal conductor (such as electrical circuit wiring) inside an external conductor (such as an aluminum hull) is at the same potential as the external conductor. However, once large lightning currents flow inductive and resistive volatges can form, so that interconnection is a good idea. However, if this is not allowed, we address this by adding a connector with an air gap between the hull (that is, the main lightning conductor) and the electrical system "green" wire |