If

you have any additional questions that should appear here, please send us

an email.

Frequently

asked questions about our products

We specialize in the manufacture of the following items:

· SiedarcTM - spark-promoting grounding electrodes embedded in Marelon through-hulls; · HStripTM – 0.5 ft2 tinned solid copper grounding strip. As a service we also address some commonly held misconceptions and more general questions that have little to do with our products.

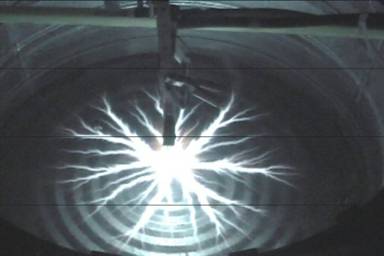

A. Yes. We (Ewen Thomson, Ken Elder and Richard

Cohen) conducted some tests with a 10 kV voltage source using KENNICK Inc.'s generator. One of the experiments was as

follows. An electrode was placed

with its tip about 4 mm above the surface of sea water from the

The

picture on the right shows the sparking extent for one test. Note that the ~15" diameter of the

sparks is about 100x larger than what would be expected between flat

plates. A particularly interesting

feature of the sparks is their occurrence in the air just above the water surface. Similar tests done with

immersed electrodes resulted in entirely different phenomena - a glow

discharge rather than spark formation occurring over a much smaller

distance (~ 1/2" diameter).

Despite

the low voltage of these experiments, the observed mechanism of spark

channel formation in the air just above the water surface is consistent

with other scientists' interpretation of much larger sparks and actual lightning. One explanation is that the sparks attach to charges on the surface

of the water. This observation is

the reason why we suggest that our SiedarcTM electrodes should be installed just above the water surface.

Q. Can the electrode survive a 100% lightning current? A. No lightning conductor can withstand 100%

of all lightning strikes. The main

problem is overheating from long continuing currents,

that occur in about half of all lightnings and are responsible for fire ignition. Physically, there is about a 10V voltage across the

electrode-discharge interface. Hence

for a charge of say 10 C, the electrode tip is subject to 100 J of

heating. However, once the tip

starts melting, no further temperature increase is possible since the metal

vapor disperses. Without going into

further proprietary details, we pay careful attention to these factors in

the design of our electrodes. As a

starting point, we adopted an engineering approach and designed each

electrode to the same specification as that advocated by NFPA 780 for an air terminal for a Class II

lightning– a 1/2" diameter solid copper rod with a shaped

tip. Tin electroplating is added for

superior corrosion resistance and compatibility with connectors inside the

boat.

Q. Why

is the electrode/cable connection over engineered?

A In our experience, the weakest link of

any lightning protection system is each connection. To make the best possible connection to

each SiedarcTM electrode we get each

one rotary swaged using the same process as that used for standing

rigging. Were it not for the tin in

the connecting cable, it would be almost impossible to discern where the

cable begins and the connector begins after the swage.

Q. Do current or pending standards allow for sparking grounding electrodes? A. ABYC TE4 allows

for supplemental grounding conductors, as does the 2008 version of NFPA 760

HStripTM

Q. What is significant about an area of one square foot? A. One square foot is a nice round number. It turns out (see Concepts) that a typical lightning current flowing uniformly out of a 1 ft2 ground area immersed in salt water generates a fairly low voltage of about 11kV. However, even in sea water sideflashes have caused hull damage when there was too large a distance between the mast and the grounding surface and the connecting cable was too close to the hull. In fresh water the voltages generated are large enough to cause sideflashes from multiple conducting fittings. As Thomson,1991 concludes "the 1 ft2 is shown to be hopelessly inadequate to prevent sideflashes in fresh water". In fact, of more importance than the area is the shape of the grounding surface. A square 1 ft2 plate has a grounding resistance of 0.36 ohm. In contrast, our HStripTM with dimensions of 0.36" x 2" has only half the area but less resistance (0.29 ohm). Also, if we split the traditional one square foot area into two strips, we can place each near the periphery of the boat to allow for externally-routed connections but still have a total area equal to that required in the standards. Q. What do you recommend for the through-hull penetration? A. Each through hull penetration is a

potential source of water leakage into the hull and, in a water soaked

hull, the connection through the hull couples the lightning current into

this hull moisture. The result can

be multiple blow outs from the hull moisture through the gel coat and into

the water, where the extent of damage depends on the whim of the

lightning. Since the internal damage

is invariably masked by the hull coating, it is very difficult to ascertain

this. So, for each hull penetration

we recommend careful attention to the hole treatment to ensure as large a lay up of insulating

and waterproof insulation between the hull and the connector. We also use proprietary techniques in our

connector design to minimize the risk of sparks forming from the connector.

Q. Why do you recommend 1/0 or 2AWG cable whereas ABYC says #4 is adequate? A. Many years ago the recommended cable size for down conductors in standards was #8 AWG. This changed after the publication of earlier scientific calculations of heating in cables in Thomson,1991 showing that a large lightning current could cause #8 copper cable to melt. In addition, actual observations indicated failure of #8 gauge wire. So #4AWG was chosen based on these heating curves. However, other research performed by Dr. John Tobbias indicated that even #4 gauge copper shielding wire could rupture at large current owing to the magnetic pinch effect. So we recommend 1/0 or 2 AWG gauge for all major connections. Q. Can I lower drag by embedding the strip flush with the hull? A. Since the sharp edges of the HStripTM are designed to form sparks, these

should remain exposed. However, 1 mm

(.04") or so should be enough for this purpose. So, yes, but leave about 1 mm protruding.

Q. Why should the ground strip be made of solid tinned copper? A. With the price of copper heading into the stratosphere, a cheaper product could be made using sintering to introduce cavities into the metal. Unfortunately, despite many opinions to the contrary, this does not lower the resistance when used as a lightning ground. The scientific explanation comes directly from the definition of ground resistance

where the symbols

have their conventional meaning. The

dot product in the denominator means that only the perpendicular component to the current density J contributes to the total

current. Merely increasing the total

surface area of S does not increase the current I and has negligible effect

on the electric field E. So the resistance of a solid immersed

conductor is theoretically the same as the resistance of one that has a

pitted surface. One very undesirable

consequence of filling a grounding conductor with holes is that there is

now less metal so that the resistance of the conductor itself is larger and

hence it is more likely to heat up when lightning flows through it. Add in the water that is inside the holes, and we now have the potential for some of the

current to flow inside confined pockets of water. It takes little imagination to work out

what is likely to happen if this water reaches its boiling point.

As for tinning, we tin plate all of our

cuprous metals, including brass and bronze, to improve their corrosion

resistance. This is consistent with

our philosophy to make all of our products to the highest possible

standards. And if we do not like the

standards, we rewrite them!

Common misconceptions & questions

A

temporary system is adequate?

First

of all, it is difficult to conceive of any temporary measure that could be

classified as a "system". See the next question for more on this. But a fundamental problem with any

temporary measure, independent of its effectiveness, is well demonstrated

by this first hand account from Joe & Kathy Siudzinski's report of

The wind drops off and eventually goes back to the north, but there is LOTS of lightning coming in from the west. Using the radar, I pick out a big cell moving fast towards us and after plotting it I decide to go north to avoid it because there is a lot of lightning to the south. This works, barely, as all this horrible stuff passes a couple of miles behind us. Now, this isn't just inter-cloud lightning, this is huge massive bolts coming down and hitting the water! We try to compare notes with the other two boats - even though we are very close, we can barely hear each other on either the VHF or SSB. Anyway, the boat in front goes south while we and the one behind us continue northwards. Big mistake. To make a long story short, we spent eight hours surrounded by lightning and occasionally some incredibly heavy rain. Why we didn't get hit, I'll never know, because we repeatedly ended up right smack dab in the middle of the storm cells. I was too chicken to go out there and install my home-made grounding rod (battery cable terminated in a copper water pipe which I strap onto the mast) as by the time I realized there was lightning it was too late. I put our backup GPS, a compass, and a hand-held VHF into the BBQ (Faraday Cage). Should have put one of the computers in there also. Kept the radar and engines going the whole time, the boat nicely steering itself on autopilot. Winds weren't too strong after the initial lashing, maybe up to 20. Kept the mainsail up and on the fourth reef and locked dead amidships with the two preventers and mainsheet. This was one of the most awesome and spectacular events in my life - if we weren't right inside these humongous thunderstorms, I would have loved watching it. As it was, those sizzling bolts coming down into the water not far from the boat were the most fearsome things I've ever witnessed. This was continuous incessant lightning and not just a bolt here and there - it was daylight out there! The smell of ozone permeated the air. Would you believe I forgot that I now have a camcorder on board! Anyway, I spent the time alternating between setting the engines and autopilot to what I thought would avoid the major upcoming nasties (totally unsuccessful in this) and then curling up next to Kathy on the bunk down below. A pillow over the head minimizes the flashing lights. I think we both got religion last night. While in the middle of one of the last nasty chunks of thunderstorm that I failed to avoid, I bit the bullet and turned the boat south and after we got out of that one we were able to avoid the few remaining nasties. It was over with by At least the boat got washed. The other two boats came through unscathed, but each caught with a man on deck stowing sails when the winds hit. Kathy's doing fine, figuring it's just another strange ritual one goes through when sailing a boat across the ocean. This reminds me (Ewen) of my first

attempt at a lightning protection in my Mirage 5.5 on its maiden cruise to

What IS a lightning protection

"system"?

In the context of lightning protection, the word "system" can be reasonably interpreted using the definition "a combination of interacting or interdependent components, assembled to carry out one or more functions". The interacting components are the various parts such as air terminals, main conductors, connectors, and grounding terminals, that are assembled, that is, installed and connected, to perform the function of minimizing the damaging effects of lightning. There are several potentially damaging effects, such as heating, fire ignition, high voltage transients, sparks, electric and magnetic field interactions, hazardous voltage formation, etc., and an integrated protection system requires a sufficient number and distribution of all parts in order to accomplish its desired function of minimizing the probability of any damage. In concrete terms we consider a lightning protection system to have:

Since, in addition, our system is a lightning protection system for a boat, we need to add another set of requirements that are appropriate for any marine system, such as:

Now reread the above question and mark off the

deficiencies.

Liability is less if nothing is done?

There is a belief amongst some manufacturers that if they install a lightning protection system that then fails they are more liable than if they had done nothing at all. There is no obligation to do this as standards are not mandatory and are intended mainly to improve personal safety, not to assure it. However, there is solid evidence that even perfunctory adherence, such as grounding a mast to keel bolts, decreases damage. Hence this argument would tend to fail the "due diligence" requirement. Gary Crist J.D. addresses this argument in "When

lightning strikes" published in Golf Course Management, pp. 21-22, April 1996 as follows: "Many

people incorrectly believe that liability is best avoided by doing

nothing. Those who assert this illogical argument believe their

approach disassociates them from the hazard, rendering them not responsible

for any resulting damage or injury. Such thinking is legally

incorrect, to say nothing of its utter insensitivity." While Dr. Crist was referring to lightning hazards on golf

courses, the same reasoning applies to lightning protection of boats.

Other

legal points are raised by Krupnick et al. in

"Lightning injuries: Electrical, medical and legal aspects" pp.

157-194, by Andrews, Copper, Darveniza and Mackerras (eds.) CRC Press,

1992. Specifically, they point out on page 158 that although the

phenomenon of lightning is beyond man's control and therefore correctly

deemed an "Act of God", when someone in a position of

responsibility does not take reasonable measures to protect against injury

and damage they may be held liable. They state "It is generally

held that if injury or damage results from the lightning strike and,

concurrently, an act of negligence committed by a responsible person, such

person cannot escape liability if the injury or damage would not have

occurred except for the persons failure to exercise due care."

In the context of lightning and yachts, it would seem that a lightning protection system is a reasonable measure to take to insure the safety of all on board. Perhaps the best argument against the do-nothing approach is that liability claims only follow after costly damage or injury and the best way to minimize the risk of these is to install the best system possible. A protection system just attracts

lightning?

A

common, and dangerous, misconception is that

an ungrounded mast is less likely to get struck than one that is

grounded. It is dangerous because this is frequently given as a good

reason to leave a boat with no protection system. The point was addressed in a University

of Florida research project whose conclusion was a resounding

"No" based on the experiences of marine surveyors: grounding a sailboat mast does not cause an increased risk of a lightning strike".

Educational materials in the form of a pamphlet and video are available on line, and the section concerning grounding vs. no

grounding is here.

Note that in this survey and its discussion in the pamphlet,

"grounding" and "lightning protection" were

synonymous. Specifically, one of the questions asked of the surveyors was "How many of these sailboats had a

lightning grounding system, that is, had

the base of their mast bonded to the keelbolts or

a ground plate under the boat".

In fact, finding the answer to this question was one of the primary

objectives of the University of Florida study. Theoretical arguments

without experimental data are of limited use because of the complexity and

lack of understanding of the attachment process. For example, recent

work at New Mexico Tech indicates that the upward going streamer is preceded by short (~microsecond duration)

current pulses rather than suddenly turning on. And who could

have predicted from theory that blunt lightning

rods work much better than sharp ones? So we attempted to get some data

by saturating the Lake Lanier and Lake Norman areas with posters requesting

that we be notified if anyone was struck by lightning. Unfortunately,

no notifications came in. So the surveyor's survey was the

less-desirable alternative. Can I reduce my insurance

premium?

An effective LPS lowers the risk of damage and decreases insurance claims in several ways: (1) In a well grounded and bonded system, the risk of personal injury, and therefore a liability claim, is decreased. Cost/benefit ratios can be very small. For example, the cabin space below a deck-mounted mast and above a keel bolt is at high risk of a connecting spark, a risk that can be virtually eliminated by adding a bulkhead below the mast and connecting the mast base vertically to the keel bolt. (2) Although the survivability of electronics systems is extremely difficult to guarantee, a network of lightning conductors that surrounds the systems provides a good shield. Also, measures such as common cable harnesses, twisted wire pairs, and transient suppressors used, for example, in telecommunication facilities are likely to increase the chances. A frequent problem is that all electronics systems are incapacitated, include the CDI system in outboard motors. Any protection system that helps to ensure that key propulsion and control systems are functional after a lightning strike will decrease the risk of both personal injury and loss of the boat. (3) According to Boat US the cost of repair to a submerged boat is about 40% of the boat value. Hence if a lightning strike blows out a through-hull transducer, the resulting hole could form the basis of a very expensive claim. While the risk of this happening cannot be eliminated, appropriate protective measures can significantly lower this risk. As an example, consider a fisherman with a metal superstructure surrounding the helm and the usual cluster of instruments. Invariably the speedometer or fish finder is located in the hull directly below the instrument cluster and connected to it via narrow gauge wires. A likely path for a lightning strike is down the VHF antenna into the instrument cluster, down the narrow gauge wire to the speedometer transducer, and into the water. Since the transducer has not been designed with lightning in mind, a blow out is probable. The above reasons would appear to dictate an answer of "Yes" to the question "Can I reduce my insurance premium?" In actuality, it is much more complicated as any premium reductions would need to be assessed according to guidelines relating risk abatement to lightning protection measures. For example, a boat either has a carbon monoxide detector or it does not, but the same cannot be said of a LPS since each boat is different and the type and degree of protection depends on the individual boat type. For example, in a small open boat the main concern is to avoid a direct lightning strike to a person, but in an offshore fisherman an equally pressing need is for survivability of propulsion and control. To further complicate matters, a LPS should always be installed during manufacture but this adds costs that will probably not be recouped by the owner in reduced premiums. On the other hand, the insurer also has the prerogative of raising deductibles and denying coverage and so can further influence the decision of the owners, and through them the OEM's, to demand adequate protection. Our dream ship is 55'-75' long

and made of steel. If you were to own such a vessel, how would you protect

it?

A steel hull means that the risk of holes being blown through the hull present in fiberglass and wooden boats is virtually eliminated, although it is possible that a through-hull could still blow out or some damage to the hull surface could occur at the exit points. Also, reports of damage to propellers and engine electronics may indicate that uncoated immersed fittings (propellers, bow and stern thrusters, unpainted thruhulls) provide preferred paths. Hence, even in a metal vessel it is advisable to add grounding strips outboard of these immersed fittings. We are still assessing the role of Siedarc electrodesTM in metal hulls. The remaining concerns are then protection of (i) crew, and; (ii) electronics. Crew protection reduces to two further cases (a) direct strikes, and; (b) sideflashes.

(i) (a) Crew

protection from direct strikes The objective here is to ensure

that lightning does not attach to any place on the deck, that is, where a

crew member might be standing. As an illustration of an effective but

extreme measure, NASA at

Vertical conductors afford some protection for the surrounding area by attracting lightning attachment to their top, or, more accurately, by preferentially launching an upward-going streamer to intercept the downward-going leader. This concept has been summed up in the term "cone of protection". However, in practice the cone is rather leaky as it is based on probability rather than certainty - a better name for it would be the "sieve of protection"! Hence nearby lightning rods lower the risk of nearby attachment, but do not eliminate it. Much better protection is afforded inside metallic stays. In the case of a passage maker with a small aft mast the area inside the stays could be considered well protected, but almost no protection is offered outside this area. Anchoring during a thunderstorm on this ship would be a hazardous occupation. Note that the mechanism for lightning attachment is unaffected by the material used in the hull and whether the mast(s) are grounded or not. (i) (b) Crew protection from side flashes A sideflash is a spark that travels (usually) between the main lightning conductor and a nearby conductor - water (both in water tanks on the boat and the water it is floating in) and crew members both being considered conductors. However, if the lightning attachment point, for example a mast, is not connected to a grounding conductor in the water then a major sideflash may be more vertical than horizontal and carry a large proportion of the lightning current - several tens of kiloamps. Sideflashes can also occur in a boat whose main lightning conductor IS well grounded. As a result of the high voltage caused by the lightning current, discharges may form between the main conductor and any nearby conductors. Bonding is the answer to this problem, but the bonded conductor is then raised to the voltage of the lightning and this needs to be taken into account. Not that this is bad - birds can perch on high voltage lines without injury - but it may create problem areas near the water, which is closer to "ground" voltage, especially in fiberglass and wooden hulls. In fact, in order to prevent sideflashes the whole boat needs to be raised to the potential of the lightning conductor. This is much easier to do in a steel or aluminum ship since the whole hull can be incorporated into the bonding system. However, if the cabin and pilothouse are fiberglass or wood, separate conductors need to be added for the main down conductor system and the bonding system. When adding these care needs to be taken that the conductors do not cause galvanic corrosion of the hull. (b) Protection of electronics Lightning damage to electronics is a major problem since the combination of low-voltage equipment such as computers, remote transducers (e.g. weather instruments, radar, radio antennas), and close lightning is a very bad mix. To make matters worse, a direct strike is not necessary - electronics can be blown from nearby lightning as a result of induced currents flowing off masts, etc. Devices such as transient voltage protectors are designed to limit voltages entering electronic circuits and the incorporation of these on circuit boards significantly increases their chances of surviving a close or direct strike. In addition, equipment layout and the harnessing of interconnecting cables is crucial. There are some fundamental principals that need to be followed to reduce the risk of damage, but it can never be reduced to zero. As in all types of lightning protection, it is a case of improving the odds. From my past work on sailboats, the chance of damage to at least some electronics was more than 90%, and to all electronics, 40-70%. A "protected" boat in this study was considered to be one with a grounded mast. This minimal level of protection improved the odds in fresh water, but there was no difference in salt water. Hence merely grounding the mast was not enough to improve the survivability of electronics. I have no data on relative electronics damage in steel hulled ships. From a theoretical point of view, a fiberglass superstructure between a metallic mast and a steel hulled ship can be regarded as an insulating filling in a conducting sandwich. If no precautions are taken, both the bottom of the mast and the top of the steel hull may simultaneously launch multiple sparks to complete the lightning's path to ground.

|